Solutions for a Smarter Future

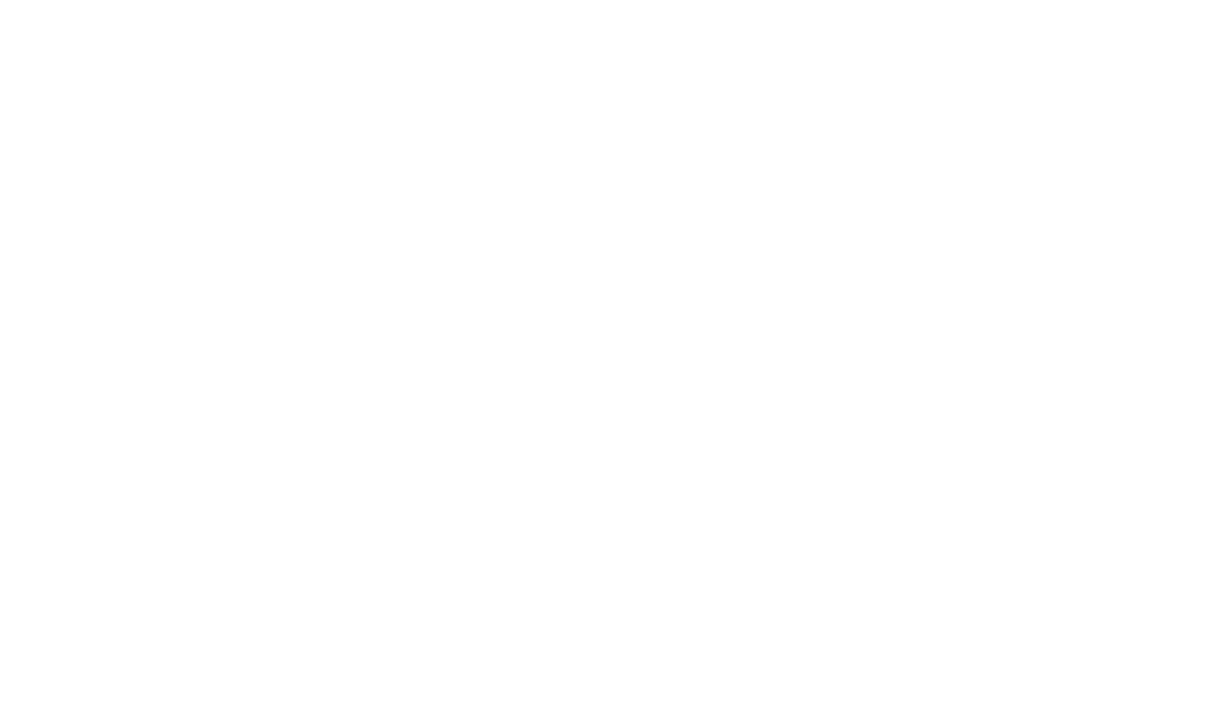

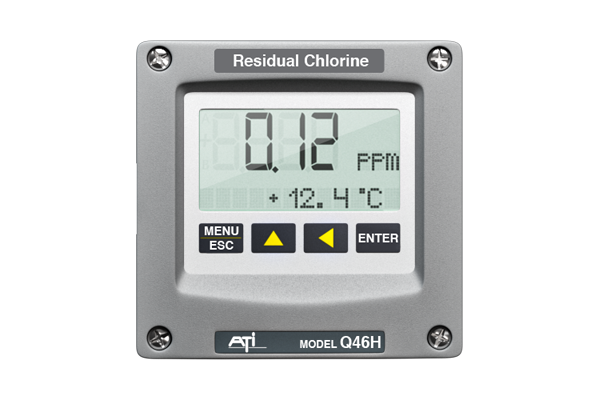

ATi are global leaders in the design, development and manufacture of electrochemical sensor monitoring solutions for water quality and gas detection applications, helping to drive the sustainable use of the world’s most precious resources.

Synonymous with water quality and gas monitoring excellence, we have 30 years’ experience in pioneering the development and deployment of innovative, customer-focused solutions with class-leading support.

Our flexible range of monitors are trusted by some of the largest businesses and brands across diverse markets and applications, including potable water, waste water, industrial, food & beverage, HVAC, healthcare & pharmaceutical.

As part of the Badger Meter group, along with s::can GmbH, we are passionate about delivering Solutions for a Smarter Future with technology you can trust and unparalleled reliability.

Network digitalisation with MetriNet solutions

Watch how our modular, below ground level, Kiwa UK Reg 4 approved MetriNet smart water quality monitoring solution comes together, to deliver continuous, online, reliable data through our ultra low-powered, digital M-Node sensors.

MetriNet is also available as a Street Level Smart Water Quality Monitoring solution, housed within a serviceable, flame retardant and vandal resistant telemetry bollard to enable distributed water quality monitoring, without the concerns associated with below ground-level installations.

Find out moreA team of experts, ready to help

A global company with a caring culture. We have a team of experts on hand to help with any product or support query you may have. Contact us and experience ATi’s exemplary customer support.

Get in touchOur Clients

Our envied list of clients reaches globally from some of the world’s largest water utilities and pharmaceutical companies, to world-renowned global drinks manufacturers. ATi strives to be more than a company that just supplies instrumentation, but a company that changes the way customers view the supply of monitoring equipment. Expert industry knowledge and high quality equipment, combined with industry-leading customer service and support, are key to our success.

Click here to see US contact details

Click here to see US contact details  Click here to see UK contact details

Click here to see UK contact details